HGTP, is the leading provider of industrial gas turbine maintenance solutions. We provide parts, repairs, and field services with a dedication to maximizing power producing equipment's availability, reliability, and efficiency. The fuel nozzle and combustion component repairs at our newest facility ensure optimal performance and reduce strain on gas turbine parts..

MD&A Fuel Nozzle Services at our Hangzhou Service Center services and supports GE® gas turbine Frame 5 fuel nozzles, Frame 6 fuel nozzles, Frame 7 fuel nozzles, and Frame 9 fuel nozzles, including standard, Multi-Nozzle Quiet Combustor (MNQC) and Dry Low NOx System (DLN) 1.0, 2.0 and 2.6 for industrial and power generation customers.

Our advanced engineering expertise combined with leading-edge equipment delivers reliable, extended life for new or refurbished fuel nozzle products. Lean manufacturing principles, and a commitment to quality improvement, maximizes customer value.

We have a new on-site Portable In-Situ Air Flow Test Stand that allows for immediate and conclusive data on gas turbine nozzle performance while still remaining attached! On-site, MD&A can utilize the Fuel Nozzle Air Flow Test Stand results to confirm or deny that a particular nozzle is the cause of non-ideal unit operation. During the testing process fuel nozzles remain attached to the gas turbine end covers. Individual nozzle operation is compared with neighboring nozzles or available benchmark data. The best part is, no outage is needed! The benefits include cost savings, outage and extended downtime can be avoided and it requires minimal test time and labor.

Maintenance of Fuel Nozzles: How Important Is It?

Gas turbine fuel nozzles are essential parts that are crucial to the combustion process. They immediately affect the turbine's overall performance, emissions, and efficiency by atomizing and supplying fuel to the combustion chamber. Fuel nozzles may get worn, clogged, and damaged over time due to operating demands, pollutants, or natural deterioration. Regular maintenance and prompt replacement of these components are necessary to guarantee optimum turbine performance and lengthen the equipment's lifespan.

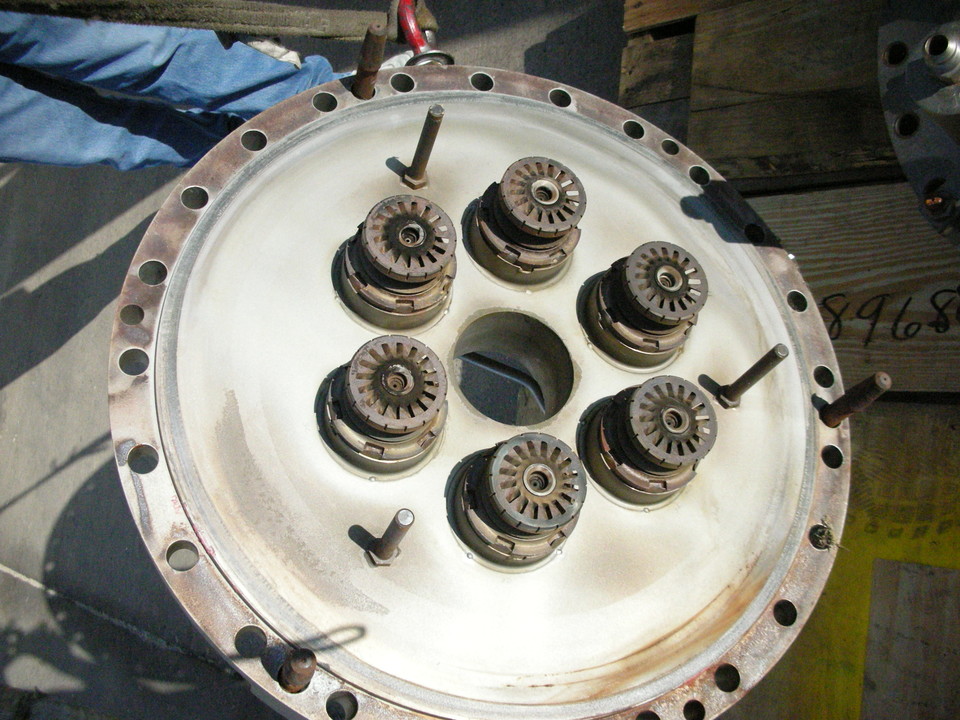

Fuel Nozzle Repair Process at Hgtp

Hgtp built its Nexgen fuel nozzle center of excellence to offer the best possible fuel nozzle repairs. By maintaining a constant testing temperature of 70°F, our specialized climate-controlled facility guarantees a regulated atmosphere for the repair procedure. For various gas turbines, including designs from GE, Siemens, and other top producers, we can fix single-fuel, dual-fuel, and tri-fuel assemblies.

The fuel nozzle repair follows a rigorous and meticulous approach to guarantee superior results. It involves:

Incoming Flow Testing: Each fuel nozzle undergoes thorough incoming flow testing to assess its current performance and identify any existing issues.

Dimensions and Disassembly: To prepare the nozzle for repair, our knowledgeable specialists carefully measure its dimensions and disassemble each component.

NDE and Ultrasonic Cleaning: We use cutting-edge ultrasonic cleaning processes to remove impurities and deposits from the nozzles. A non-destructive examination (NDE) is performed to find any concealed flaws.

Component Testing and Reassembly: The fuel nozzle components are rigorously tested to ensure they meet the required specifications. The parts are expertly and precisely rebuilt after successful testing.

Final Flow Testing: Each repaired fuel nozzle is tested after reassembly to ensure it performs as intended and complies with NG requirements.

Engineering Reports: The client is given incoming and final engineering reports that describe the repair procedure and outcomes.

Advanced Testing Equipment and Techniques

At HGTP, we understand the value of precise and trustworthy testing in fuel nozzle repair. We use state-of-the-art testing tools and abide by industry standards to guarantee the greatest degree of precision. Our fuel oil and natural gas circuit testing procedures are created to adhere to ISO 5167 requirements.

Using desiccant and refrigerant systems, we utilize air as the testing medium for natural gas circuits after it has been dried. For mass air flow testing, sonic nozzles with a binary area progression provide precise results. The testing equipment offers a repeatability greater than +/- 0.25% and an excellent accuracy of +/- 0.48% of measurements, traceable to NIST standards.

Conversely, water or #2 distillate tests fuel oil circuits, and Coriolis meters are used to monitor mass flow rates. This testing instrument can accurately measure flow and mass flow rate within a pressure range of 35 to 350 psi.

Wide Range of Supported Gas Turbine Models

The fuel nozzle repair services provided by APG are available for a wide variety of gas turbine types, including:

GE Frame 3, 5, 6B, 6FA, 7B-EA, 7F.03/.04/.05, 9E.03, 9F.03/.04

Siemens SW101/171/191, SW251, SW501D, SW501F, SW501AA, SGT400, SW501B

Various Combustion Systems, including Standard Combustors, LEC I, LEC III, DLN 1.0, DLN 2.0, and DLN 2.6

Our skilled engineers and technicians are knowledgeable about the complex operations of these gas turbines, enabling us to provide specialized repairs that meet the particular needs of each type.