Company dynamics

Turbomachinery, Turbine, Pump, and Aerospace Components

Turbomachinery, Turbine, Pump, and Aerospace Components

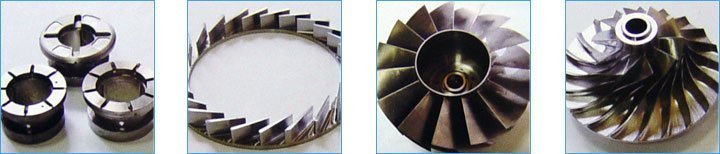

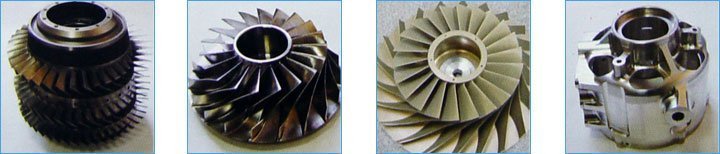

We are a supplier of precision machined turbines, turbine components, shrouded compressors, blisks, and impellers. Our products are used in the power generation, oil & gas and rotary equipment industry. As an AS9001-certified facility, we also supply precision machined components for aerospace and defense industries such as nozzles, aircraft ribs, and other aerospace components.

Our facility incorporates the latest 5-axis machining centers, vertical machining centers, coordinate measuring machines, and other testing equipment. We also use a proprietary and superior tool path software for precision machining of turbine components such as axial-type compressors resulting for competitive quality and cost.

Business Areas

Reverse Engineering Services | Turbine Blades, Pumps, Compressors

We precision machine turbine components, compressor components, and pump components through reverse engineering for rotary equipment manufacturers seeking part suppliers as well as for repair, refurbishment and replacements. Our process includes performing 3D coordinate measuring of the existing turbine, data sculpting, 3D modeling, technical data package (TDP) creation, and machining of the final product.

Turbine Components

Turbine Blades

Seal Strips (OEM specification available)

Turbine Pins

Fasteners (Stud bolt, plain round nut, fixing bolts, etc)

Locking Strips

Sealing Plates

Assembly Seals

Sela Wires, Elements

Gas Turbine Components (OEM specification available)

Turbine Startup Accelerator

Impulse Turbine Blade

Reaction Turbine Blades

Hydrodynamic Bearings (Visit Bearing Product Page)

Compressor Components

Centrifugal Compressor Impeller

Centrifugal Compressor Wheel

Disk

Centrifugal Compressor Fans and Blowers

Inlet Volute Chamber

Axial Flow Compressor Blades (Rotors)

Axial Flow Compressor Vanes (Stators)

Compressor Blisk

Pump Components

Centrifugal Pump Volute Chamber (Casing)

Turbo Pump Impeller

Radial Impeller

Volute Chamber

Aerospace

Spacecraft Components

Aircraft Structural Components

High Pressure Turbopumps

Defense

Localization of Key Components (Army, Navy, Air Force)

System Assembly Projects (A.P.U & E.C.S)

Development of Technology Civil & Military Use

5-axis Machining Technology for Turbomachinery, Aerospace, Defense, and Precision Machinery Quality

Our in-house 5-axis machining is used for machining shapes that are usually not machinable by general 3-axis machining. 5-axis machining is mainly used for aircraft, turbine parts, tire molds. Our simultaneous 5-axis control equipment can process complex curved surfaces and it eliminates the need to produce special tools or jigs for the parts, reducing production costs, and shortening the machining time and setup time. 5-axis machining is an excellent process for production of smaller quantity of various different kinds of components because product development time is also shortened.

Manufacturing Process

CAD/CAM Programs

TCT-CAM (Proprietary software for greater accuracy and efficiency in processing impellers and blades)

CATIA V5

VERICUT (NC Toolpath Simulation)

NeuroCAD (3D Auto Measuring Software)

MASTERCAM (Turning & Milling CAM Software)

HyperMill (5-Axis CAM Software)

Categories

News & Events

Contact Us

Contact: Hangzhou Gas Turbine Parts Co.Ltd

Phone: 15869109368

Tel: 86-571-89967020

E-mail: saels@gas-turbine-parts.com

Add: No151,ZiDingXiang Road Hangzhou City ZheJiang China 310021